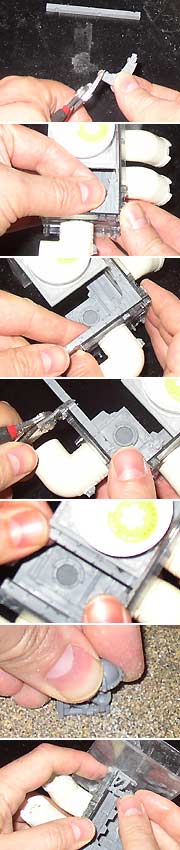

Then glue the extracted skull detail onto the top of the 90 degree elbow pipe for a bit of added detail!

Next, grab that juice drink lid, sand the top and bottom so it will

glue better, and keep it handy.

Around the neck of the juice bottle, you will often find a plastic ring

that snaps free of the cap when the cap is removed. Using whatever

tools work best (I use my teeth of course), carefully pry this ring off

the bottle, by working your way around and pushing upward. (If you

get desperate, you can cut the top of the bottle off and slide the ring

off from there). If you are lucky (as I was with this Welch's bottle),

you'll find that the ring has some hidden detail folded underneath itself.

Take advantage of this detail by gluing the ring onto the top of your bottle

cap, forming a raised lip of detail.

Next, you can add more surface detail to the cap by gluing whatever

you like inside. I used a spare large tape reel I had from another

dismantled cassette, and added a small reel below the notch.

Finally, glue the bottom of the cap to the floor plate (I usually glue

to the smoother side). This whole assembly can now be glued up inside

the Ventilator. Line the panel up so that it fits in the corner formed

by the tape box and the upper tape case. I like to position it so

that the cap sticks out just a bit past the edge of the tape case.

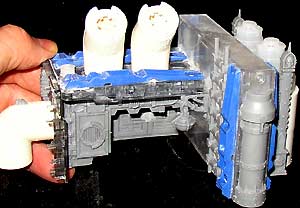

Now glue the eagle bracket into the back outside corner of the assembly,

opposite the juice cap, as shown here.

Next, glue a bulkhead strip to the inside wall right below the eagle

bracket.

Once the glue is dry, clip off the excess bulkhead with nippy cutters.

The remainder of the bulkhead can be glued adjacent to the floor panel

(with the juice cap on it) to form a nice finished edge as shown here.

Now grab the globe lamp piece and sand the top edge flat on your sanding

pad.

This enables you to glue it into the front inside corner, forming a bracket between the roof and the tape box as shown here.

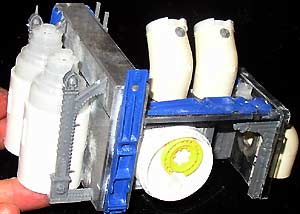

Sand the backs of the clothespins so they glue better.

Two of the clothespins halves can be glued to the rooftop as shown here,

for extra detail. If they are a bit too long to fit, trim off a little

with your Nippy cutters. You should be able to fit them in on either

side of the vents, as shown here.

Add two more on either side of the tape box, at the long end.

Now sand down the inside of the pipe half and glue it onto the end of

the tape box.

Once the glue is dry, you can trim down the excess protruding clothespin

with nippy cutters. Once clipped, sand the ends lightly with sandpaper

to smooth them out.

Finally, Add one more clothespin to the end of the tape box opposite the pipe half, and clip it down as well.

Now glue it in place on the tape box, between the clothespins and the

roof.

To prepare the side vents, start by sanding one side of the 3/4" PVC

couplers flat, opposite any raised ridges on the side of the coupler.

This will help it make better contact with the flat tape box. You

can also sand the ends smooth if they have any rough spots.

Next, prepare the water bottle pop top lids by removing the pop top

(yes, I used my teeth again, sadly). Sand the bottom edge of the

lid and add glue to it.

Press the lid onto one end of the PVC coupler- do this for both lids

and couplers to make two side vents. You can add extra glue around

the edge if you're worried about strength.

Remember sanding the side of the coupler flat? Now add glue on

that side and glue it to the tape box, about a half inch in from the short

end of the box. Glue the second coupler on the same way, right next

to the first.

The flying buttresses will frame these side vents, but first you'll

want to carefully saw off the round grid detail off the "inside" sides

of the buttresses for a better fit.

Don't let that detail go to waste- glue the round grid details onto

your rooftop vents as shown here for an extra bit of industrial flavor!

Now you can glue the buttresses in place against the tape box, on either

side of the side vents. Be sure to glue the bottom of the buttresses

where they contact the side vents, for extra strength.

And finally, that tiny little detail piece from the Basilica sprue (I call it an exhaust). Glue it to the short side of the Ventilator, offset from the pipe, for a hint of industrial detail.

STC VENTILATOR

STC VENTILATOR